27.09.2019 ERASMUS+ project INLEARC first transnational meeting (kick-off) took place in Tallinn

During the meeting, project partners were introduced, overview of the project objectives, intellectual outputs and expected results were given, tasks between partners were specified and dissemination activities were discussed. Also tasks and activities for creating intellectual outputs (O1-A1, O1-A2, O2-A1) in next period were agreed.

INLEARC project visited Norcar BSB Eesti AS for collaboration in preparing work-based smart learning materials

We are grateful that Norcar BSB Eesti AS collaborates with our project in preparing smart AI based e-learning materials. Norcar BSB Eesti AS is an affiliate company of the concern from Finlandia Norcar-BSB OY. Estonian branch has grown over 4000m2 production space company and 80% of production is for export. The company’s main products are tractors’ body components and agricultural equipment. The company’s prefabricated compiled details are used to make miniloaders Norcar and feeding tractors Minkomatic. At the same time Norcar BSB Eesti AS produces a variety of mechanical engineering components and nodes (cylinders, oil tanks, variable size hatch latch.

19.02.-20.02.2020 ERASMUS+ project INLEARC second transnational meeting took place in Seinajoki University of Applied Sciences in Finland

Seinajoki University of Applied Sciences – SeAMK is known is known for teaching modern high-tech subjects and is involved in several international projects in this field. The main topic of the Seinajoki meeting was the coordination of creating the content of study materials in the field of robotics and the use of e-learning opportunities in the development of study materials. The laboratories and teaching methods in the field of robotics were introduced by SeAMK to other partners. All parties presented and explained the robot systems implemented in the companies of different countries participating in the project and their operating principles.

INLEARC team developed a work-based learning concept to apply AI based smart-learning materials (O2-A1)

The aim of work-based learning is to make the learning process more practical, directly related to production, to involve students in creative work and to see the real applicability of what has been learned or what is necessary to study. Work-based learning may be organised as internships, job shadowing, business / industry field trips, entrepreneurial experience, cooperative education, school-based enterprise, service learning, etc.

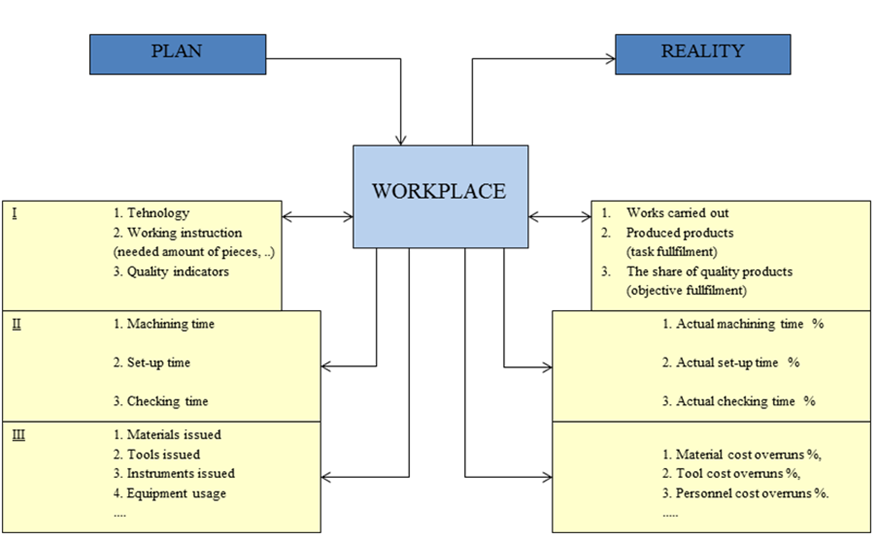

Work-based learning is very tightly connected with the manufacturing, production system and in particular with the workplace. Workplace is a single unit of a production system that is organized on the basis of machine tool (or group of machine tools) serviced by an operator (or industrial robot) and additional servicing equipment if needed.

Terms and ideas were analysed and clarified inside the team and for the development of AI-based smart e-learning materials to support the whole concept in learning (in the field of robotics and mechatronics). Each INLEARC project country (Estonia, Latvia, Finland) demonstrated the concept with one company experiment – bringing company into the education with modern software and digital tools (visualization, 360 degrees views, technical simulations, videos etc).

The INLEARC team prepared a description of the functionality of the robot sections (O1-A1)

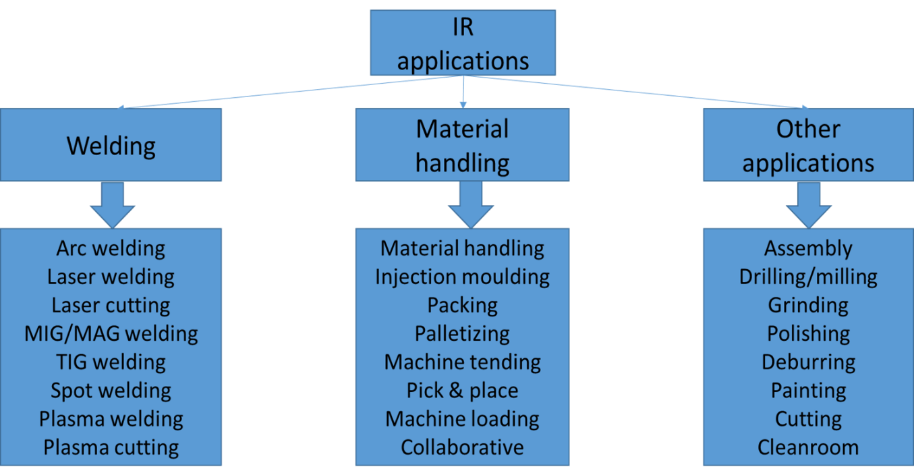

The main idea of the output was to examine different types of robot cells in each partner country. During this output, our project members visited industrial companies to carry out a survery to determine the functionality of each robot cell examined. A total of 12 companies were visited from Estonia, Latvia and Finland, and the main areas of activity in the robotics departments were:

- Welding,

- Assembly,

- CNC machine tending,

- Bending,

- Palletizing and storage.

In the course of the analysis, the level of automation of robot cells and programming methods were assessed. Also the possibilities of how to further develop the existing robot sections were assessed. Also how to apply real examples from industry in the learning process. Selected example industries will provide input for the development of training courses in partner countries.

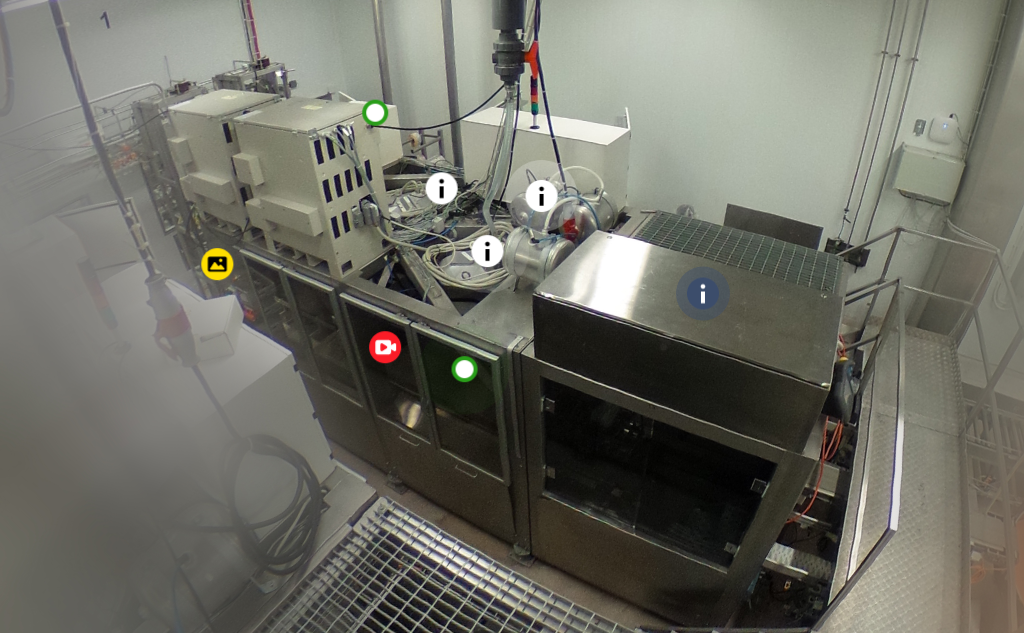

Robot cell description (O1/A1) prepared in Finland

Seamk’s project team visited a local and globally operating company Atria PLC which is one of the leading meat and food companies in Northern Europe. The goal of the visit was to start the project’s activities regarding robot cell descriptions. Atria’s representatives kindly let us analyze and describe one of their robotized packing lines and activities around it. Seamk’s project team chose to utilize 360 camera technology to capture robot cell functionality from various perspectives. The 360 images and videos were later put together in a ThingLink platform which is an environment for presenting 360 images and videos and for creating interactive functionality over the material. Overall, the project team managed to analyze the robot cell functionality and employee roles regarding the packing line very well. The company representatives were also surprised how well the 360-imaging technology was able to capture so much information and they saw some potential use cases for the technology in their operations.

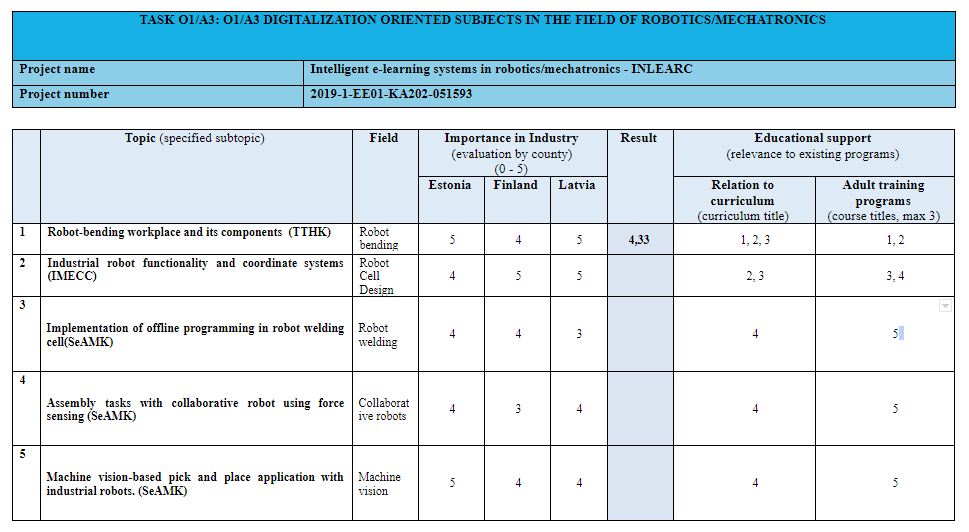

The needs of Industry are guiding the way in digitalized learing in the field of robotics and mechatronics

The main goal of the activity (O1-A3) was to compile a list on the basis of which to start creating digital learning materials. Descriptions of companies’ robot cells were used as input material, and the topic blocks of study materials were divided according to the areas of the examined robot cells. In addition, the importance of the necessary basic knowledge in the field of security devices for robotic systems was considered.

In addition, existing robotics and mechatronics curricula and adult training programs in partner countries were examined to ensure coherence and provide theoretical background. By the end of the activity, a 15-thematic digital learning materials program was structured to be used as input for the development of learning materials on the Moodle platform to ensure a common way to share data between partner countries. Below is a section of the door as an example of topics.

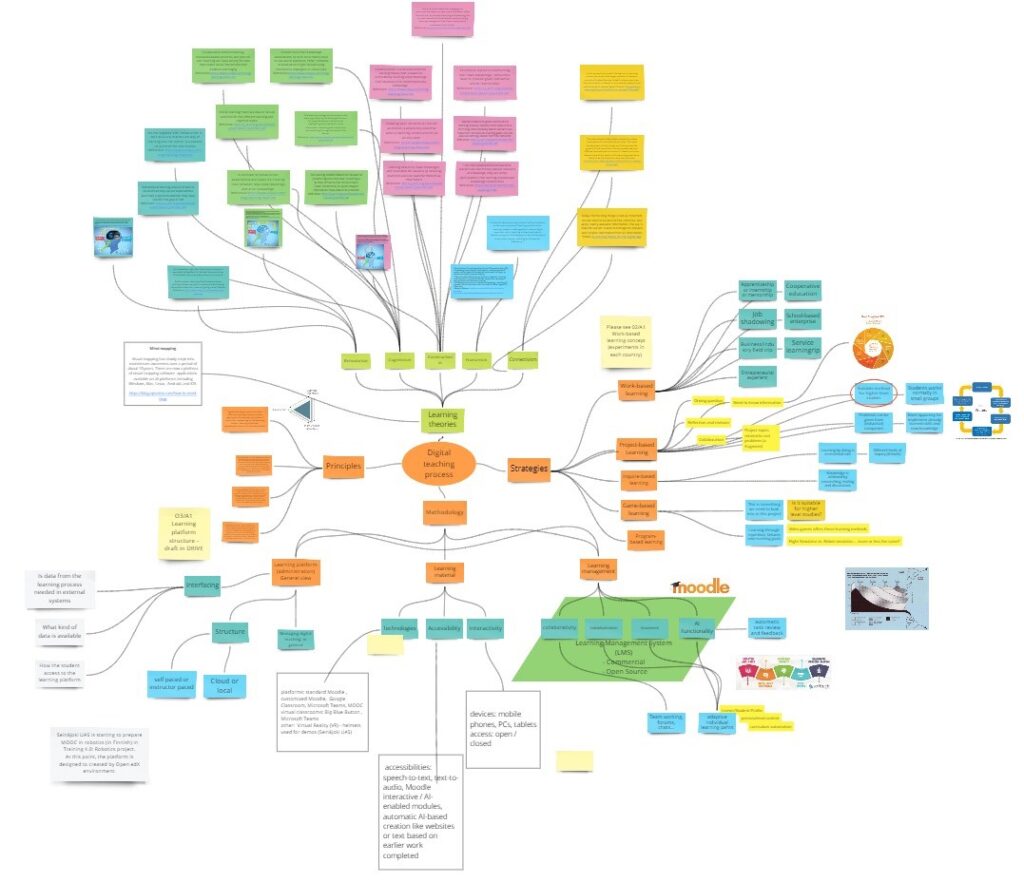

Short overview of O1/A4

Seamk-led activity ”Strategy, methods, and principles for the digital teaching process development” from the project’s output 1, started with a collaborative ideation work to achieve a joint view for the development process framework. Collaboration was arranged using the Miro platform which is a web-based intuitive visual tool for real-time collaboration. During three workshops, the project team created a comprehensive scheme for the digital teaching development process based on their experiences and knowledge. Next, the project team will transfer all ideas into a report which will conclude the activity.

Short overview of O2/A2

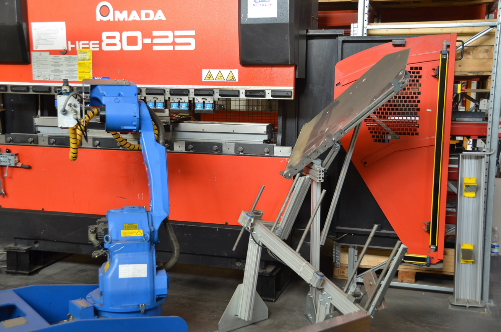

Based on the results of the project’s output 1, project partners started to develop modular-based e-learning materials in the field of robotics/mechatronics on the output 2 activity. The Estonian project team has been focusing on robot bending with a comprehensive set of use cases. The Latvian project team started with a robotic safety-related use case. The Finnish project team has been focusing to develop use cases for collaborative robot assembly and welding robot offline programming. Although there are still more to come, at this stage the project has managed to develop a cross-cutting set of e-learning material in the field of robotics and mechatronics.

Our team expert Eduard Brindfreldt introduced the INLEARC project at the international BILT conference on “New Qualifications and Competencies brings together Asia-Pacific and Europe”

BILT Conference took place virtually at the 27-28th of April 2021 and we had the honour to present the INLEARC project there by our team expert Eduard Brindfelt from Tallinn College of Industrial Engineering. Conference focused on the new vocations and the challenges related to distant (online) education to train robot technicians, robot operators and mechatronics. Eduard presented our online training materials developed during the project – robot cell descriptions, 360 degrees simulations, etc. The main topic of this sub-workshop was “Implementing new qualifications and competencies through new teaching and training approaches”. INLEARC new e-learning Moodle course “Robot bending” was also introduced. Presentation got very positive feedback from the audience, especially the work-based learning concept applied in INLEARC project – how to bring company production areas and robot sells virtually to the classroom using digital technologies and modern software.

Please see more:

https://moodle.edu.ee/course/view.php?id=32515 and here:

http://www.tthk.ee/inlearcs/robot-bending/

22.-23.09.2021 ERASMUS+ project INLEARC third transnational meeting took place in Hämeenlinna in Finland, Hosted by SEINAJOKI UNIVERSITY OF APPLIED SCIENCES (SeAMK)

The meeting concentrated on the topics of IO2, activities IO2-A2, IO2-A3 and IO2-A4 and IO3. Also Discussion and brainstorming – How we use AI in the e-learning materials? – was carried out.

12.-13.05.2022 ERASMUS+ project INLEARC fourth transnational meeting took place in Riga, Latvia, hosted by Riga Technical College (RTK)

Feedback of IO1 and activities of IO2 and IO3 were discussed. Discussion and brainstorming about using AI in e-learning materials and case-studies was carried out. Also dissemination issues were discussed.

20.05.2022 Erasmus+ INLEARC multiplier event was held in Riga, Latvia, hosted by project partner RTK.

23.08.2022 Erasmus+ INLEARC multiplier event was held in Seinajoki, Finland, organized by project partner Seamk.

24.08.2022 ERASMUS+ project INLEARC multiplier event was carried out in Tallinna Tööstushariduskeskus (TTHK).

Project team presented the results of INLEARC. Jüri Riives (IMECC) give an overview of the project, its objectives and results. Eduard Brindfeldt (TTHK) made a presentation”A smart educational platform in the field of mechatronics and robotics”. Madis Moor introduced the use cases developed during the project. Kristo Vaher (Tallinna Tehnikakõrgkool) spoke about virtual world in the industry. The event was taking place in the premises of Tallinna Tööstushariduskeskus.

The project can be considered very successful – in the framework of the project, need-based learning materials (use-cases) were developed in cooperation with partners from 3 countries (Estonia, Finland and Latvia) and were piloted in the learning process. Also, regarding use-cases, feedback was asked from industrial experts (including professional associations), educational institutions and industrial companies. We are happy to note that the developed learning materials are actively used in partner organizations and as well as, for example, in Tallinn University of Technology and Tallinna Tehnikakõrgkool.

26.08.2022 ERASMUS+ project INLEARC (Intelligent e-learning systems in robotics/mechatronics) final transnational meeting took place in Tallinn, Estonia, in the premises of Tallinn University of Technology, hosted by IMECC.

At the final seminar, the project partners met for the last time to summarize the results of the project, make plans for new collaborations. Also they had the opportunity to visit TalTech’s laboratories and demo center. The main topics of the project’s last transnational meeting were the review and final analysis of all planned activities (methodology of digital competencies in the field of robotics and mechatronics, prepared e-learning materials, feedback received on learning materials).

Project partners of INLEARC were:

- IMECC OÜ (IMECC), Estonia

- Tallinna Tööstushariduskeskus (TTHK), Estonia

- Seinäjoe Ammattikorkeakoulu (Seamk), Finland

- Riga Technical College (RTK), Latvia

Main results of INLEARC are:

- Methodology of digital competences in the field of robotics and mechatronics.

- Smart e-learning materials in robotics and mechatronics (linked with artificial intelligence).

- New e-learning materials integrated with the digital learning platform (available in the Moodle environment).

The INLEARC project ended extremely successfully! All project objectives were fulfilled. In addition to the fulfilled goals, there is a large share of the practical implementation of the project in Estonian educational institutions and partner institutions, and in addition, the cooperation between the project partners has intensified and will last also after the end of the INLEARC project.